Blog

Solid Edge Value-based licensing – an engineers perspective

If you ever find that you could use multiple Solid Edge add-on products, I recommend looking at Solid Edge Value Based licensing. It gives you access to many solutions…

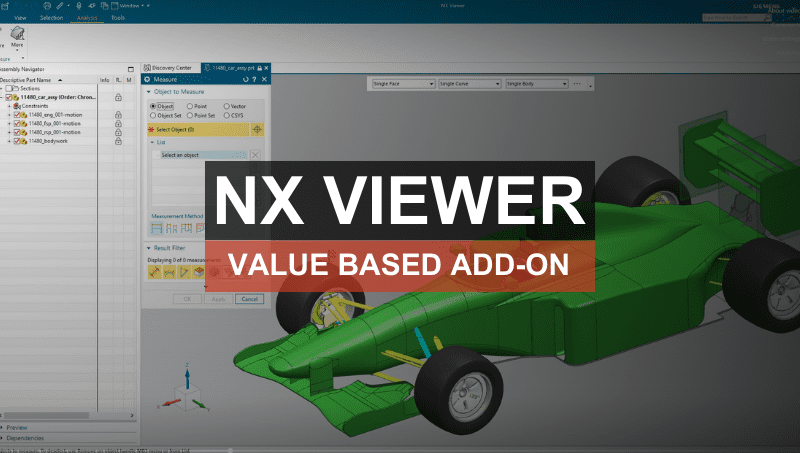

NX Viewer – Useful features, plus tips and tricks

NX Viewer is a quality product that can benefit many roles and positions at different companies. Viewer is a feature inside of the NX software that allows users to open…

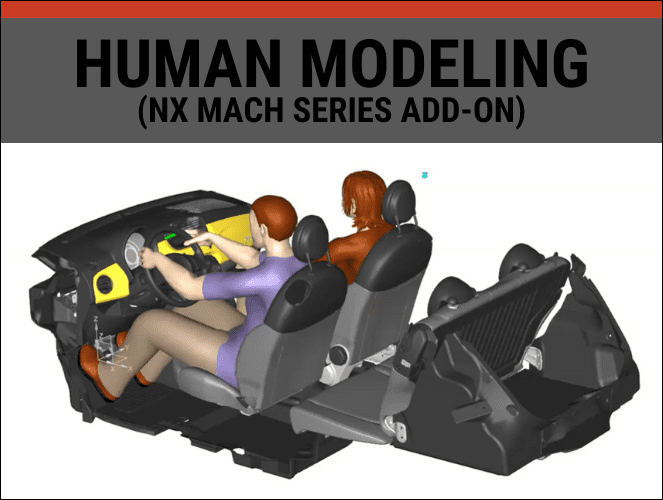

HUman modeling – nx mach series add-on modules

Human Modeling is a great add-on that utilizes large databases created by qualified universities and companies. These databases can adjust the human models…

Solid edge 2024 – our engineers favorite updates

Solid Edge 2024 empowers users to design more intelligently across every aspect of product development. With a continued focus on the user experience and…

introducing teamcenter share – new features and functions

Teamcenter Share or formerly known as Xcelerator Share, is a great cloud-based product that anyone with a SaaS license has access to. Why did…

“The Forged Tour” presented by Markforged

THURSDAY, JUNE 24, 2021 from 4:30 - 7:30 pm Join Us for "The Forged Tour" at Our New Location! Markforged and the CAM Logic, Inc. team are excited...

Solid Edge Portfolio Series Tech Pubs Webinar

Thursday, August 26, 2021 2:00 pm EDT ENSURE SATISFACTORY IN-FIELD PERFORMANCE OF YOUR PRODUCTS AND THE SUCCESS OF YOUR BUSINESS Looking for an...

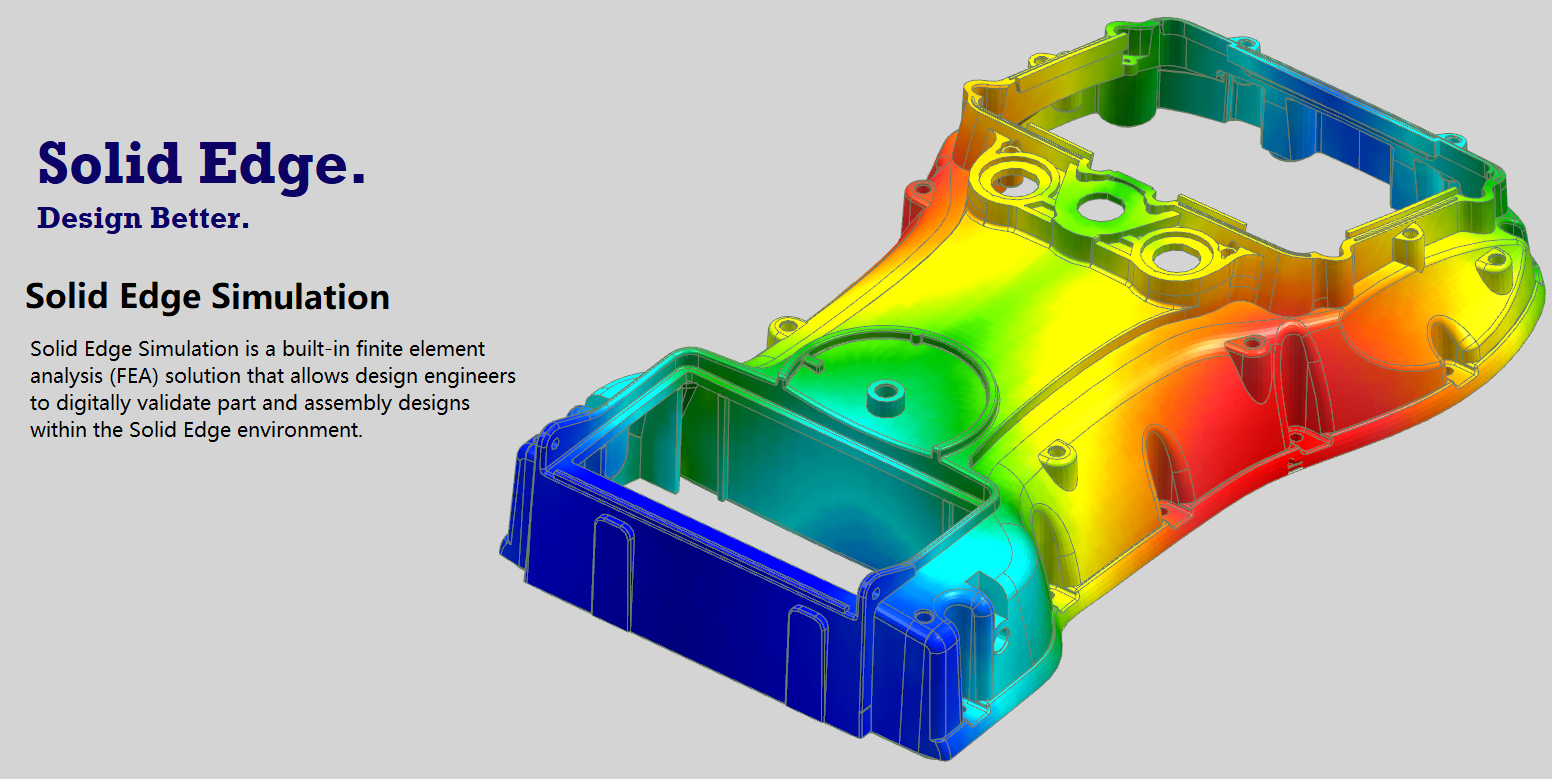

Solid Edge Portfolio Series Simulation Webinar

Thursday, June 24, 2021 2:00 pm EDT ACCELERATE DESIGN ANALYSIS & REDUCE ENGINEERING PROTOTYPES Want to solve complex fit & position...

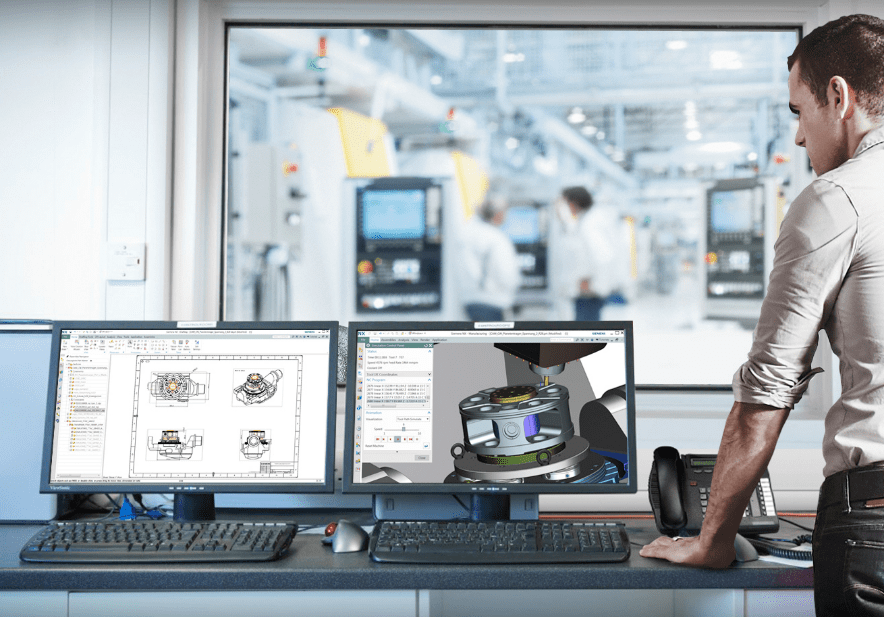

Solid Edge CAM Pro Webinar

DISCOVER ENHANCED MACHINE TOOL VALUE WITH SOLID EDGE CAM PRO WEBINAR Learn how to maximize shop floor efficiency with a single unified CAM system....

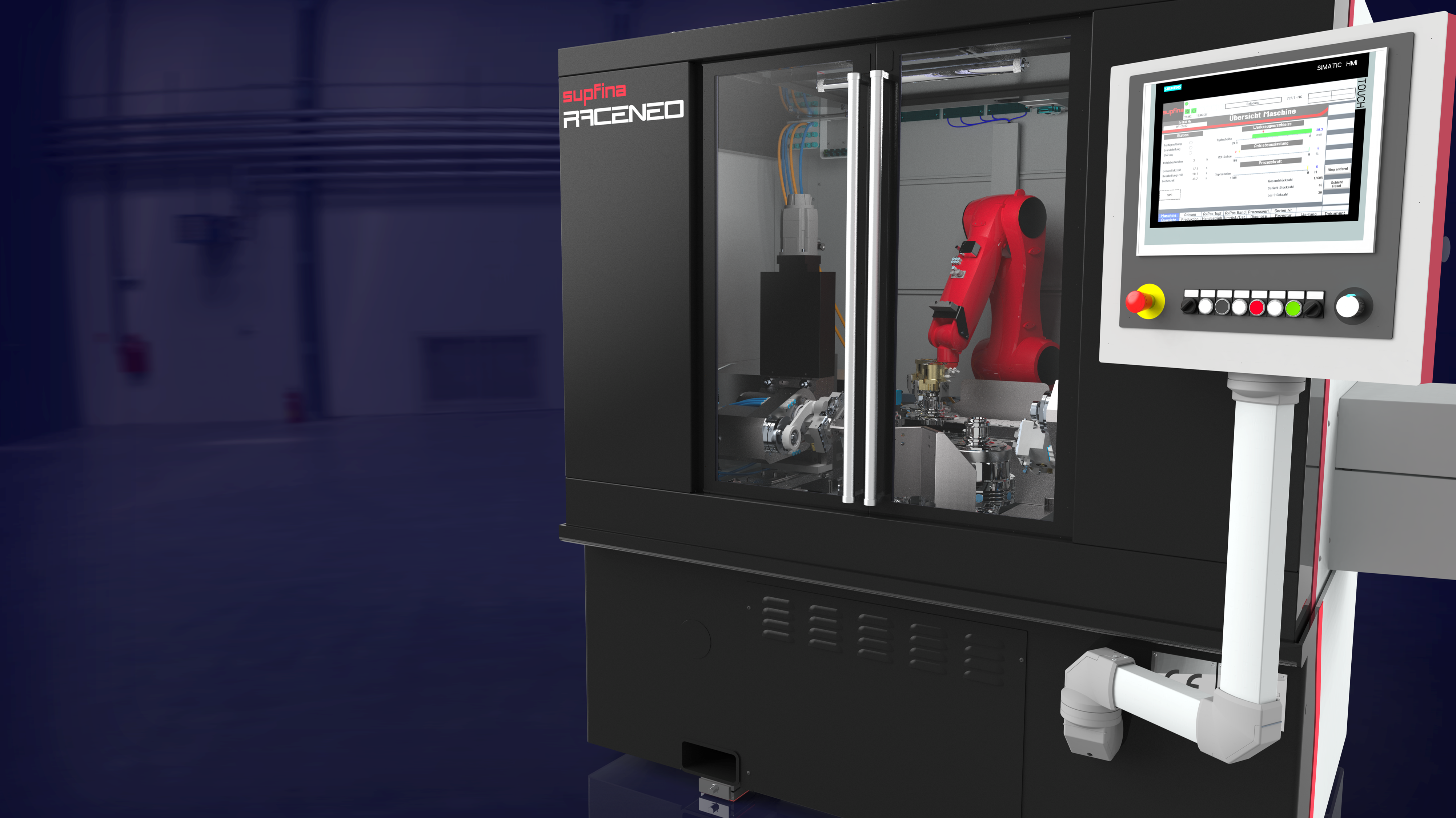

Digital Machine Shop Virtual Seminar

THURSDAY, MARCH 11, 2021 8:00 am - 12:00 pm Transform part manufacturing with the Digital Machine Shop Do you want to learn how to digitally...

3D Scanning Technologies: Laser vs. Structured Light

Over the past five years or so, the availability of 3D scanners on the market has increased dramatically. No longer is a 3D scanner only for those...

Solid Edge 2021 What’s New

Shape Search There is another exciting feature that will be revealed in the upcoming release of Solid Edge 2021. Shape Search will allow for the...

3 Reasons to Use 3D Scanning for Part Inspection

This week we’re going to take a quick break from Solid Edge 2021 to discuss three key advantages of 3D scanning over using a traditional coordinate...

Solid Edge 2021 What’s New

Reverse Engineering and Copy Paste Assembly In today’s installment of our blog series, I would like to introduce a few more exciting features and...

Solid Edge 2021 What’s New

Frame Design and Subdivision Modeling As we continue to discuss the new features that are being brought to Solid Edge 2021, we continue to be...