Frame Design and Subdivision Modeling

As we continue to discuss the new features that are being brought to Solid Edge 2021, we continue to be excited about rolling out this new functionality to our customers. This week I am going in depth on some improvements to the Frame Environment. This is a time-tested tool that received a few updates that help export the resulting information out to manufacturing. The other topic of discussion today will be the brand-new addition of the Subdivision Modeling environment. This will bring powerful surface creation tools to Solid Edge and increase its prowess for industrial design.

Frame Design

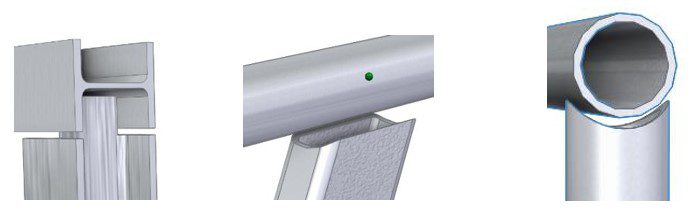

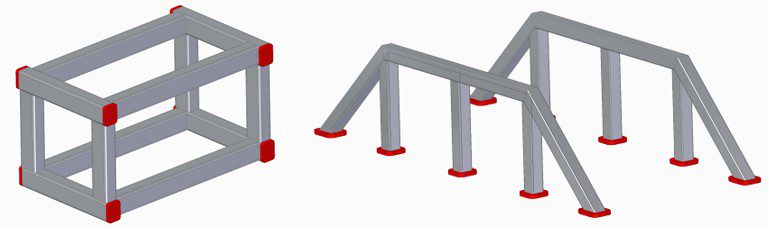

For those that may be unfamiliar, Solid Edge Frame Design takes simple 3D sketches and turns line segments into cross-sectional geometry along their axis. The sketch remains fully editable easily facilitating revisions or uses across several machine variants. The frame and end conditions will update as necessary throughout this process, creating a very dynamic workflow. The user can determine the end condition and generate a cut list easily. Now in Solid Edge 2021, there is the option to allow for weld gaps which can create results that will more closely align with your manufacturing processes. There is also a new ability to report out miter angle in a fully automated fashion.

Weld Gaps

First, the weld gaps option is a feature that many customers using frames have been asking for. So, if you haven’t heard of Frame Design, now is an even better time to give it a look. The weld gap option can be applied to an entire frame or to localized members. Of course, it can be used to allow space for weld material, but it can also be used as a tolerancing tool to ensure that parts don’t end up long. The gaps can be applied to all sorts of cases with coped ends, butt jointed ends, and where various cross sections meet.

End Caps

Another addition being made here is for the automatic creation of end caps. The drafter will have the options to define material, thickness, inset and offset values, and corner conditions. This will make it possible to specify traditional welded or pre-purchased plastic endcaps and allow for the automatic population onto the BOM.

Subdivision Modeling

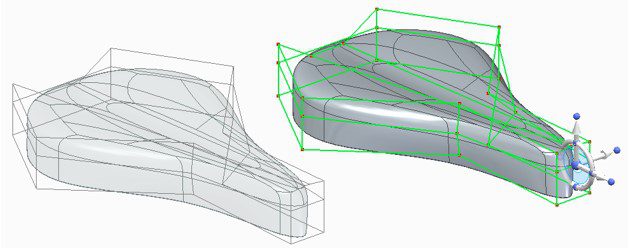

The final thing I want to share with you today is the addition of Subdivsion modeling. This is a really exciting new toolset that is being brought to Solid Edge 2021. Sometimes referred to as cage-modeling, users will manipulate a series of volumes defined by faces, edges, and vertices. The resulting free-form geometry is well-suited to industrial and product design. The thing that sets this new toolset apart from other CAD applications, is how Siemens chose to use the ‘Wheel’ to make working with this complicated geometry very intuitive. Users can simply select elements of the cage and manipulate them directly.

Stay tuned for our upcoming webinar, where I will get to show off many of these new features live. I will also be posting another piece next week when I will focus on the improvements made to the Reverse Engineering tools and other efficiency boosting tools.

Find last week’s post about Working with Large Assemblies and Sheet Metal here.