Large Assembly and Sheet Metal Improvements

Here at CAM Logic we are excited about the upcoming features that will be rolled out in the newest version of Solid Edge. Today I am going to dive deeper into two topics that will bring the most benefit and time savings to our user base. We know a great deal of engineers that use Solid Edge to design and prototype custom and production machinery from the small to industrial scale. These use cases will see assembly sizes climb into the thousands of components and very often use sheet metal parts. With this in mind, I would like to introduce some new functionality related to sheet metal workflows and an array of improvements for working with large assemblies.

First off, I think the single biggest improvement to Solid Edge 2021 is how much better it is equipped to handle large assemblies. Yes, it was already best-in-class for working with extremely large sets of data, but now it will be even better at handling these heavy part count models with less active management by the user. Many functions that were previously only possible on ‘Active’ components will now be available to use on ‘Inactive’ ones. This allows for less of the model to be fully loaded into Solid Edge, while increasing the amount of parts that can be comfortably shown on screen.

When adding new components to the assembly, you will no longer need to activate a part to create a face relationship or align a fastener to a cylinder. This means that when parts must be added to an assembly, it could be loaded as fully inactive. You won’t have to slowly and individually ‘turn on’ parts while you work. This has the capacity to change how users of large assembly models interact with their work every day. Speaking from my own experience in assembling hundreds of components at a time into large models, this will be an absolute game changer. The model will remain more responsive and work can get done faster, a real quality-of-life improvement. In addition to locating parts, it will be possible to measure to, create key points from, and complete view operations to and from Inactive parts. If a synchronous edit is needed, the software will identify the inactive parts associated and activate them as required.

There is another improvement that has been made that will make models lighter in terms of processing load. It involves how you import external or 3rd party data, and it is a new category of geometry called Internal Components. In the past, a STEP assembly that was imported would convert all the geometry into fully editable Solid Edge geometry and create part files for each of those items. Sometimes it is just known that you will not need to edit certain things that are imported. A supplier might provide you with complex engine or motor casting geometry that you have no influence over, let alone need to edit. Internal Components will allow a lightweight version of the geometry to be brought in for visualization and assembly purposes. It will also be stored in the file and not create extra files to manage. It is important to think of this as static data. Synchronous edits will not be available on these parts, and that hints at how Siemens was able to achieve such an improvement in load and save times on this new geometry classification.

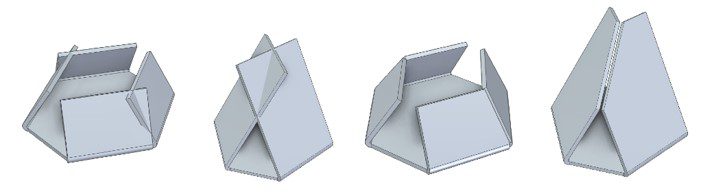

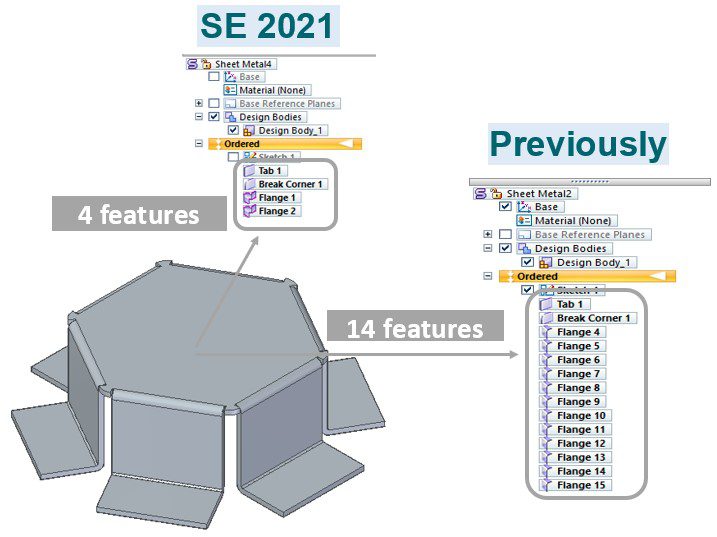

Now let’s look at the sheet metal environment of Solid Edge 2021. There is a great new timesaving command called Multi-Edge Flange. Where multiple operations used to be required, this new tool allows for complex feature and geometry creation all inside of one operation. It is also represented as a single element in the feature tree so that navigating your model is more intuitive. I would also like to point out how helpful it can be even in a simple box-break condition. The geometry does not have to be complex to benefit from the consolidation that has been brought to this new command.

Multi-Edge Flange is also equipped with a host of options that ensure your flat pattern will be generated as needed for your manufacturing process. Whether it is in-house production or 3rd party sourcing, you will have more control over how the miters are defined parametrically and output to the flat pattern. And of course, all of this remains fully editable and associative to the 3D model, making any modifications based on process or quality that much easier to remedy. There is even an automatic trimming option that will quickly take care of any self-intersecting geometry.

These are just a few of the new features that will be brought to Solid Edge 2021. Stay tuned for a live demo and upcoming webcast I will be delivering soon. Check back next week when I will dig into some new features that have been made to the Frame Environment and the new Subdivision Modeling solution that is seeing its first appearance in Solid Edge ever.