Industrial COMPOSITE

3D PrintERS

Precision-machined hardware, advanced sensors, and unique software drive leading edge accuracy and reliability. Markforged industrial carbon fiber 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with high repeatability and near-perfect surface finish.

X3™

The refined Industrial FFF 3D printer for micro carbon fiber filled nylon parts.

The X3 merges industrial quality and build volume into a benchtop form factor, bringing FFF composite 3D printing to your manufacturing floor.

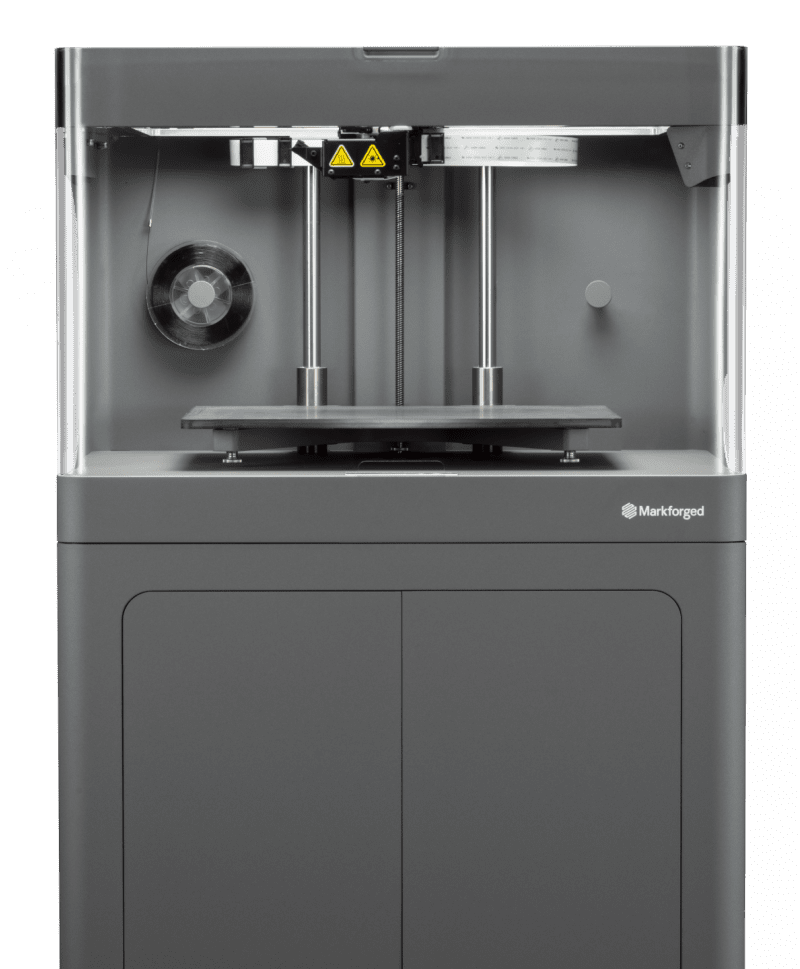

X7™

The turnkey industrial carbon fiber 3D printer for many types of functional parts.

A game changing way to get industrial-grade parts in hours, not weeks — engineers and designers can fundamentally improve manufacturing operations at light speed.

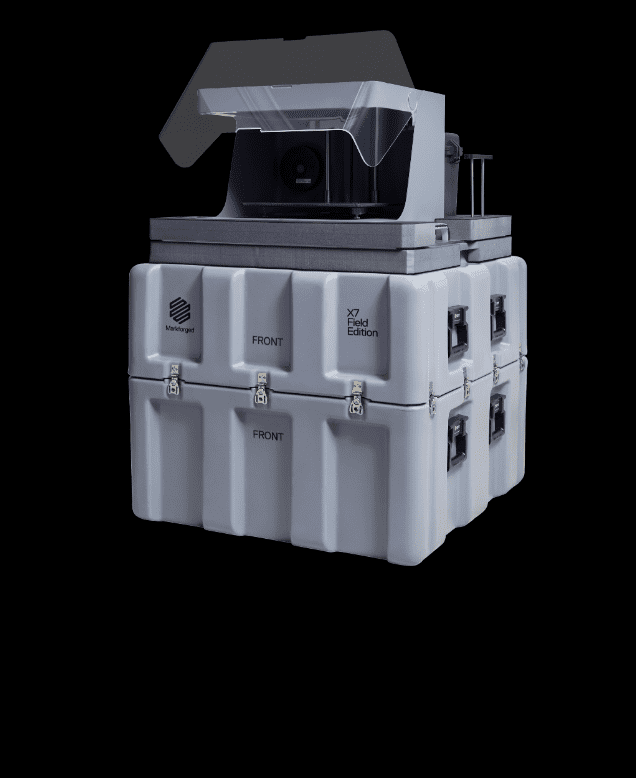

X7™ FIELD EDITION

A rugged, field-deployable industrial 3D printer for tactical response to supply challenges in remote locations.

Whether you're in the armed services, field services, or factory operations — X7 FE bridges gaps in the path from art to part, where the road is not well-traveled.

More About the Materials

CAM Logic provides a complete selection of industrial-grade 3D printing materials engineered for Markforged printers that perform under real world conditions and stand up to the demanding conditions of your manufacturing floor.

PLASTIC

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

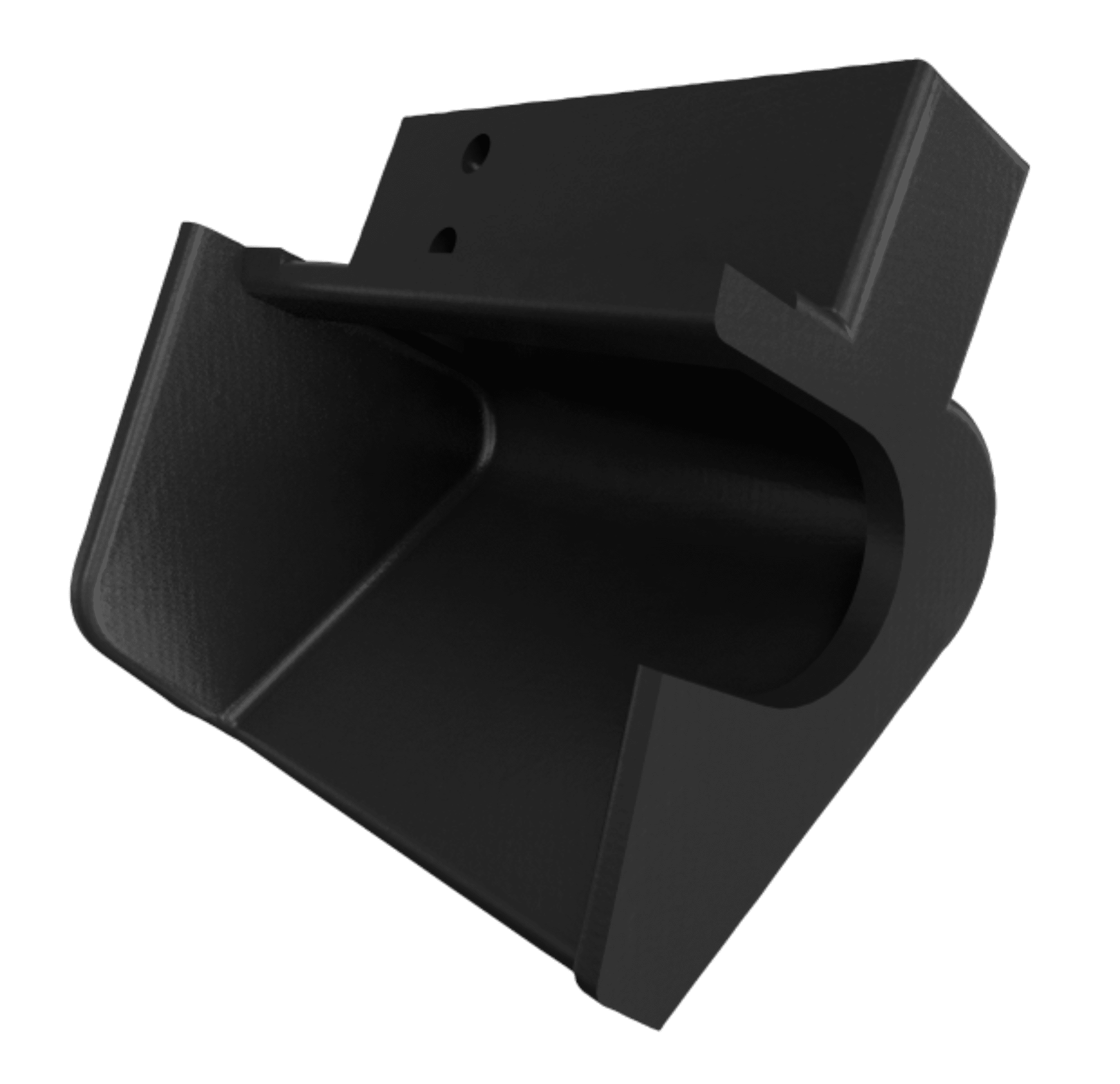

ONYX™

Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

ONYX FR™

Onyx FR is a flame-retardant variant of Onyx designed for use in applications where parts must be non-flammable. The material earned a UL Blue Card, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. It can be reinforced with any Continuous Fiber and is compatible with industrial composite 3D printers.

ONYX ESD™

Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

ULTEM™ 9085 FILAMENT

Markforged’s first high temperature printing polymer. It’s an extremely durable thermoplastic that exhibits excellent flame, smoke, and toxicity (FST) characteristics. Usable in production aerospace applications, ULTEM™ Filament brings Markforged’s CFR technology to a new realm of parts.

SMOOTH TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

PRECISE PLA

Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

NYLON

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

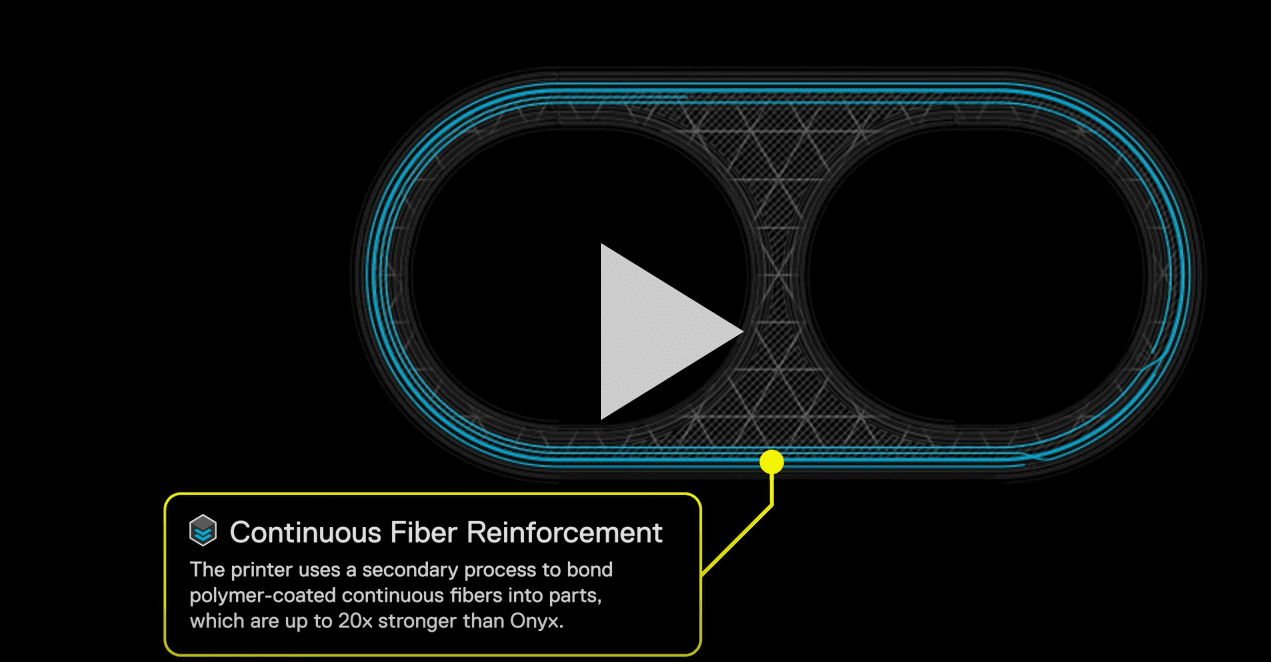

CONTINUOUS FIBER

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.

CARBON FIBER

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers. A special Carbon Fiber variant is compatible with ULTEM™ 9085 Filament.

CARBON FIBER FR

Carbon Fiber FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be precisely laid down in a wide variety of geometries. Programmatically trace curved features, reinforce holes, and mimic unidirectional fiber layups — all within a few clicks.

ARAMID FIBER (KEVLAR®)

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

HSHT FIBERGLASS

High Strength High Temperature (HSHT) Fiberglass is defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures. As a result, HSHT reinforcement is best used for parts in high-temperature environments like molds, autoclaves, and others.

FIBERGLASS

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. Fiberglass is the flagship material of the Onyx Pro and X5 and printable on the Mark Two and X7, providing a more affordable alternative to Carbon Fiber.