Why Additive Manufacturing is the Right Fit for Production Tooling

Wayne Gretzky once said, “I skate to where the puck is going to be, not to where it has been”. Having for the foresight to always be looking ahead to where the next opportunity to be successful is at leads to greatness not just on the ice but also in manufacturing. Harnessing the benefits of additive lends to manufacturers both large and small take the necessary steps to bring their companies into the next industrial revolution. Traditionally additive has been looked at as a tool for prototypes and concept models, but with the advancement, in materials, the sweet spot for additive is quickly becoming production tooling.

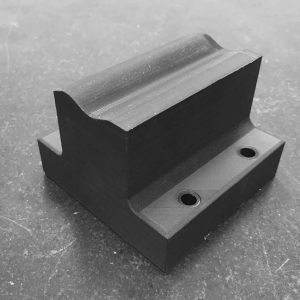

Jigs, fixtures, gripper arms, tooling guides, and low volume production are ideal applications to leverage additive. The reason is that the materials, such as the types offered by Markforged composite printing technologies, are precise, strong, and repeatable. Users of this technology can print their forming sections and fixtures generally faster and less expensive than having to put blocks of aluminum or steel on a CNC machine. Think about how much effect getting production tooling faster has on a company bottom line if you never have to say “my parts are here but we are still waiting on our fixtures to get done” why wouldn’t you look at additive manufacturing?

If this is such a great option for us why haven’t we already started using additive? The idea of using technology takes time and effort to get right. Often redesigning your tools for additive is necessary or taking a hybrid approach of traditional manufacturing with aspects of additive is the right approach. In manufacturing, there isn’t a lot of opportunities to spend the time necessary to optimize processes or that open mind needed to say, “yeah this is different, but it works”. For manufacturing that is willing to take the time to explore additive or work with a company like CAM Logic to prove solutions the benefits of additive can be substantial in cost-saving, time-saving and a massive reduction of headaches for staff.

Have a need or questions about leveraging additive manufacturing? CAM Logic has a full range of Additive Manufacturing for Production Applications and solutions ready to support your engineering and manufacturing operations.